Why Choose HJT?

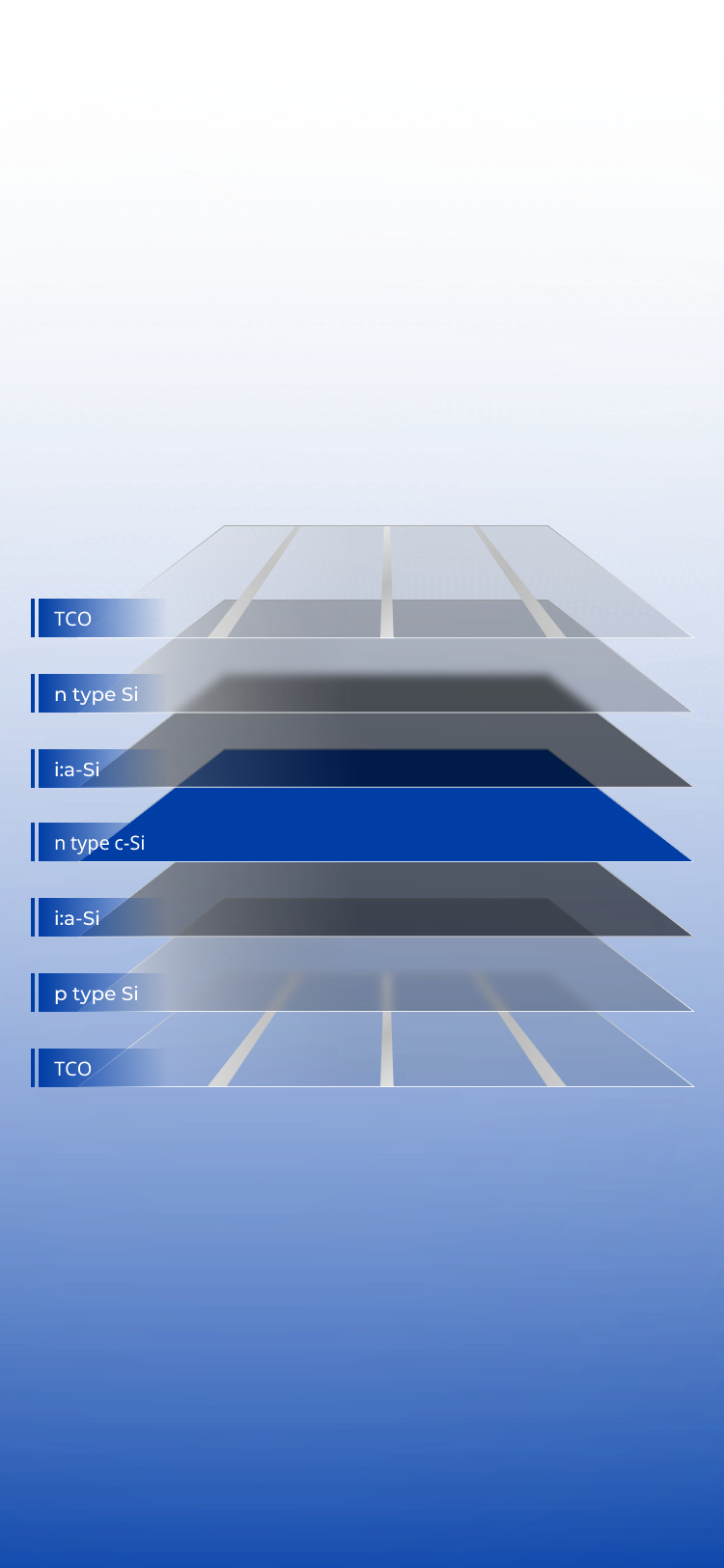

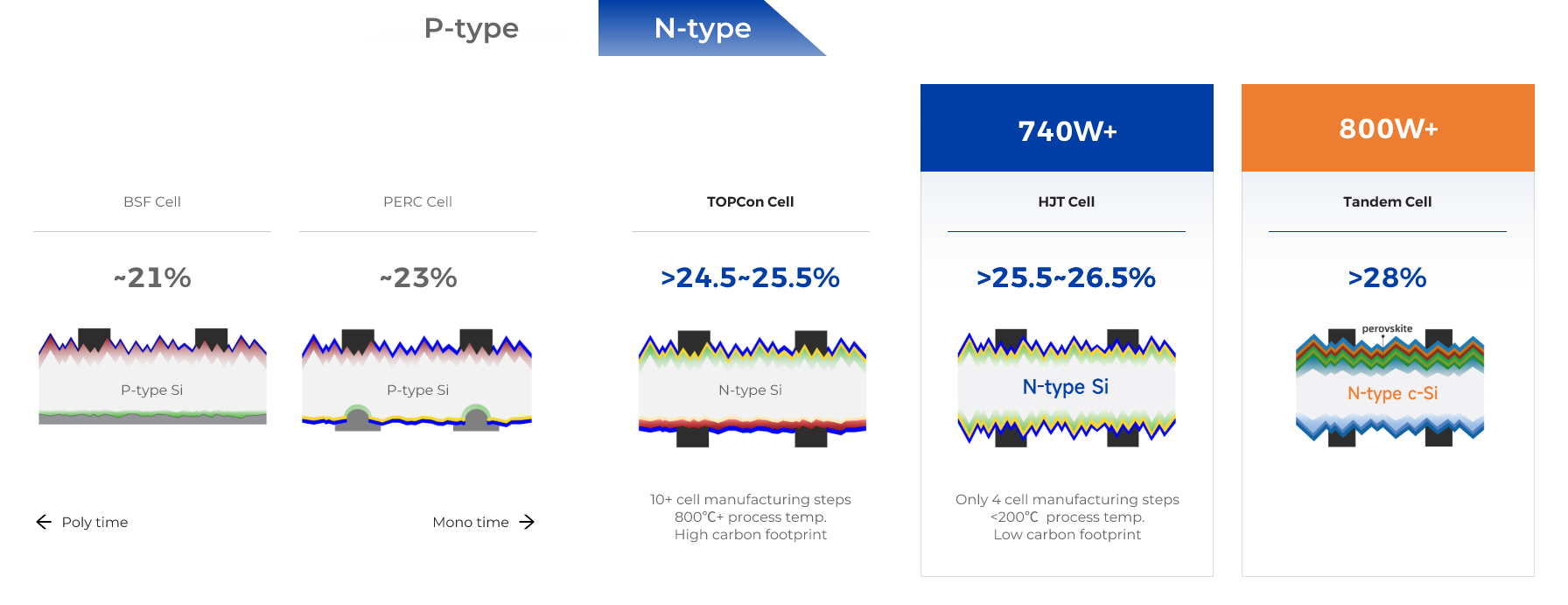

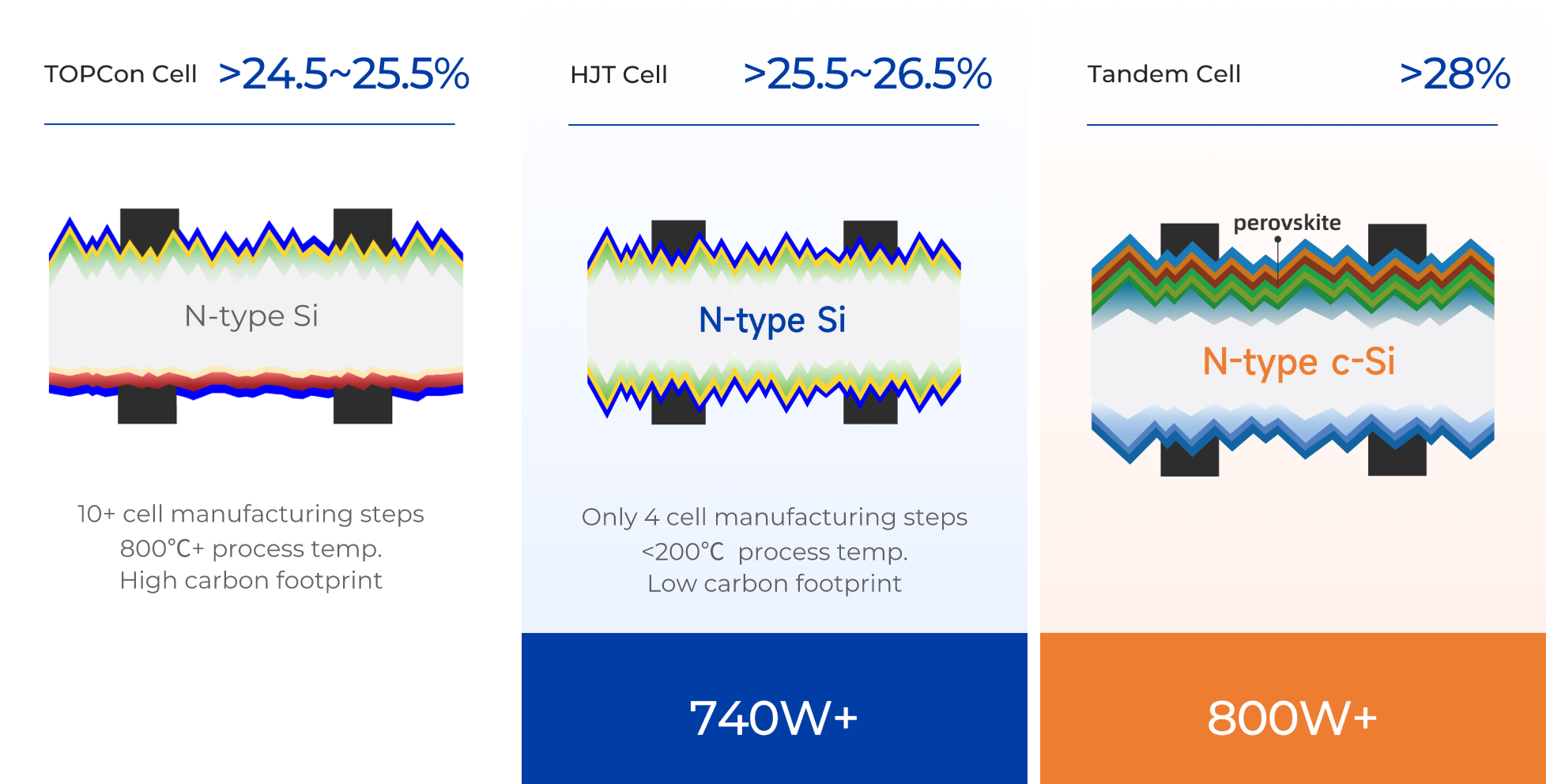

HJT cells combine the advantages of crystalline silicon and thin film technologies. With excellent light absorption and passivation effects, HJT is superior to TOPCon in efficiency and performance. It is one of the solar cell technologies that increase conversion efficiency and power output to the highest level and also represents the development direction of the next generation of cell technolgy platform.

HUASUN HJT

Potential of HJT technology

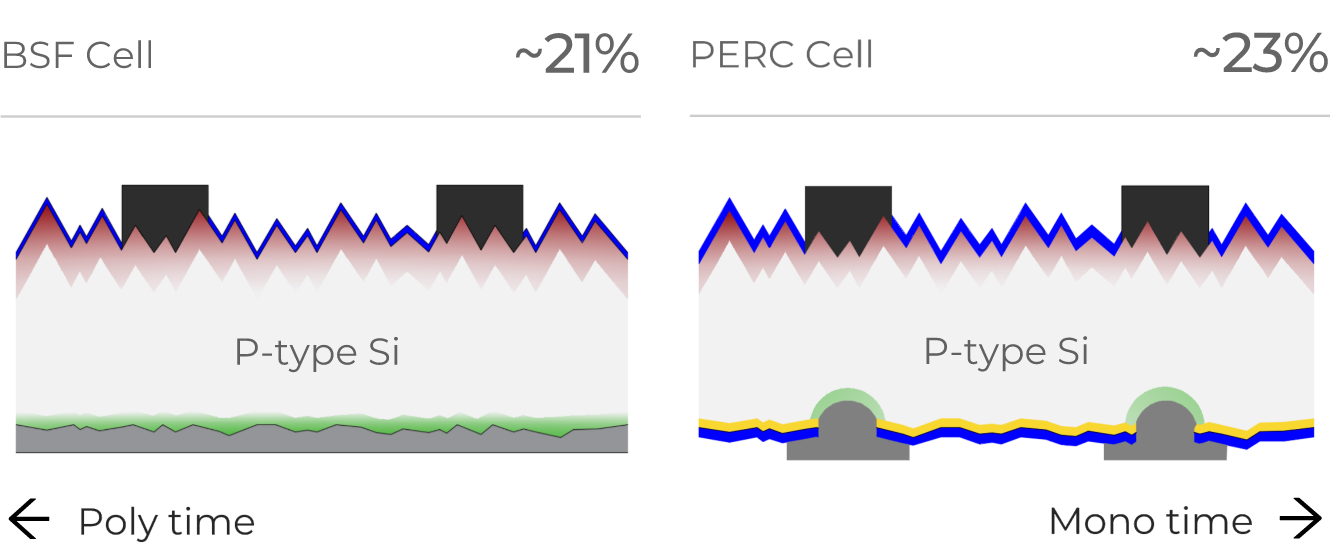

P-type

N-type

ADVANTAGES

-

Higher Conversion EfficiencyHJT solar cell uses a-Si thin-film as passivation material to reduce losses at the wafer boundaries. This method increases the open circuit voltage to 750mV and the cell efficiency over 26%.

-

More Energy YieldHJT exhibit a superior temperature coefficient, enabling them to maintain high efficiency even under elevated temperatures. Their symmetrical design bringing an excellent bifaciality further enhances energy yield by capturing more energy from the rear side.

More Energy YieldHJT exhibit a superior temperature coefficient, enabling them to maintain high efficiency even under elevated temperatures. Their symmetrical design bringing an excellent bifaciality further enhances energy yield by capturing more energy from the rear side. -

Lower Degradation RateHJT solar cells are constructed using n-type wafers, which lack B-O bonds, resulting in an exceptionally low LID. The TCO layer on the HJT solar cell ensures charge uniformity across the surface, preventing polarization and significantly reducing PID within the structure.

Lower Degradation RateHJT solar cells are constructed using n-type wafers, which lack B-O bonds, resulting in an exceptionally low LID. The TCO layer on the HJT solar cell ensures charge uniformity across the surface, preventing polarization and significantly reducing PID within the structure. -

Better Weak Light PerformanceHJT technology combines the benefits of amorphous silicon thin films, delivering superior low-light performance. Additionally, Huasun's HJT 0BB technology uses a low-shading metallization technique, further enhancing energy generation under weak light conditions.

Better Weak Light PerformanceHJT technology combines the benefits of amorphous silicon thin films, delivering superior low-light performance. Additionally, Huasun's HJT 0BB technology uses a low-shading metallization technique, further enhancing energy generation under weak light conditions. -

Thinner Wafer AdaptedHJT solar cells can be produced with 90μm wafers or even thinner without reducing the cell mechanical reliability, and it can be combined with advanced interconnection technologies such as 0BB or shingled cells, to improve efficiency even further.

Thinner Wafer AdaptedHJT solar cells can be produced with 90μm wafers or even thinner without reducing the cell mechanical reliability, and it can be combined with advanced interconnection technologies such as 0BB or shingled cells, to improve efficiency even further. -

Ultra-low Carbon FootprintHuasun's HJT modules achieved a carbon footprint of 366g CO₂ eq/W in 2023. Through ongoing technological advancements and industrialization, the company aims to reduce this footprint to an estimated 300g CO₂ eq/W.

Ultra-low Carbon FootprintHuasun's HJT modules achieved a carbon footprint of 366g CO₂ eq/W in 2023. Through ongoing technological advancements and industrialization, the company aims to reduce this footprint to an estimated 300g CO₂ eq/W.